Found a good supply of IMR 8208 XBR so I decided to work up a load for my 175 gr SMK's I like to have a few "recipes" so I can use whatever happens to be available.

The load:

175 gr SMK

Lapua 3-4 X fired brass, annealed, trimmed, and F/L sized Total indicated runout on case necks <.001".

Federal GMM primer

42.2 Gr IMR 8208 XBR

Estimated Speed ~2630 fps (Will chronograph next time at range)

The Rifle:

Remington 700 that started life as a 5-R Milspec (with Stainless Steel Action)

Benchmark 24" 5-C Barrel chambered with "No Turn" Match Reamer

Bell and Carlson Medalist Varmint/Tactical Stock

Sinclair Tactical Bipod

NightForce 12-42X56 NXS Scope

Birdshot bag filled partially with sand for rear bag.

The results:

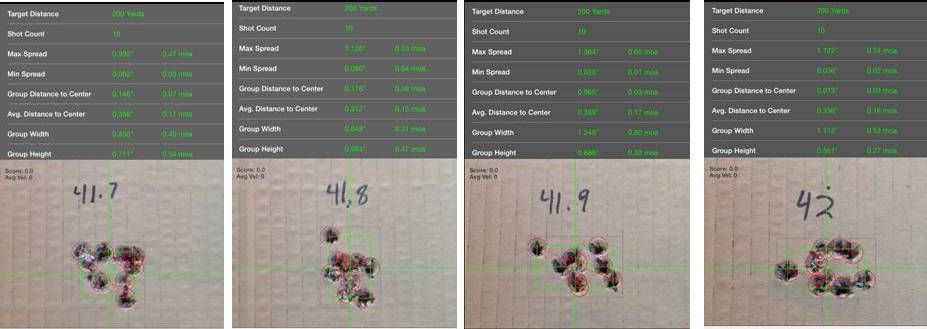

This was shot at 200 yards on a morning with fog coming and going. At times the other shooters had to stand down as they couldn't even see their 300 yard targets. I was able to just make out the orange circle and had to wait for the dot in the center to appear before pulling the trigger. The last shot was the one at the right which I fired just as the target disappeared from the scope, totally.

This was part of a workup. 5 shots per load in .3 gr increments. Started at 41 gr and was totally discouraged as the test progressed. All of a sudden, this group popped up and it's only .2 gr below published max. Rest were OK for knocking down game inside of 300 yards but not good enough for me.

Using "On Target", the 4 shot group measures a max spread of .224 MOA with an Average To Center measurement of .101 MOA. Actual measurement of the group was .469" and again, shot at 200 Yards.

When I add the 5th shot the group opens up to .457 MOA but the Average to Center remains lower at .152 MOA.

Considering that this was shot in the fog I'm good with this and am going to keep this load. Considering the "temperature resistance" of the 8208 XBR it may well be my "Winter Load". Who knows, if it keeps shooting like this for me I may even stop using Varget (like I could even buy more if I wanted to right now)

BTW, the "42 & 42.4" notes are what I'm going to use to verify this load. May even get smaller with just a little more, or just a little less.